Hot Sale High Performance Limestone Crusher Station

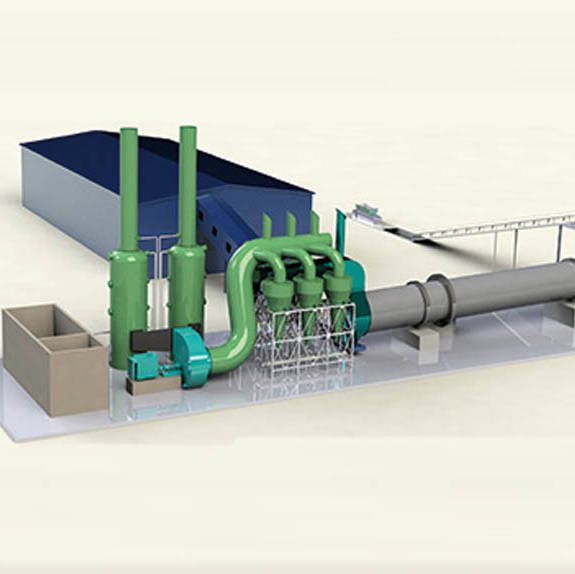

LIMESTONE CRUSHING STATION

LIMESTONE CRUSHING STATION TECHNICAL FEATURES

Our company actively responds to the call of the country to build a green mine, adopts a closed design, and builds a high-standard safety and eco-friendly limestone production line. The crushing, screening and transportation operations are all closed operations, equipped with dust removal equipment, and special dust collectors are set up at every possible dust outlet, and the collected dust is concentrated for secondary use; fully enclosed finished product silos are automatically installed. , unloading facilities, reduce dust pollution during the transportation of finished materials; realize the common development of economic benefits and environmental benefits of limestone quarry.

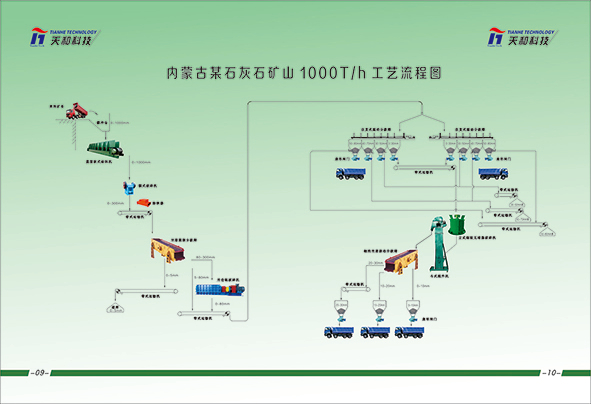

LIMESTON CRUSHER STATION FLOW CHART LAYOUT

LIMESTON CRUSHER PLANT COMPOSITION AND TECHNICAL FEATURES

※ The most advanced limestone crushing and screening system: plate feeder +PE series jaw crusher + sizing screen + double tooth roller crusher + sizing screen + fine grain shaping machine;

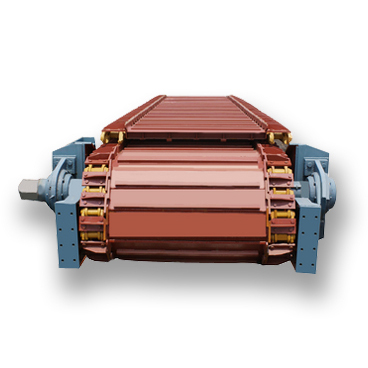

※ GBZ series heavy-duty plate feeder has the advantages of low cost, stable operation, low maintenance, uniform feeding and so on. Frequency conversion motor drive, easy to operate and control, start and adjust more stable, uniform and accurate feeding, feeding speed can be linked with the host, automatic feedback feeding, ensure the capacity of follow-up equipment to achieve the maximum efficiency;

※ PE jaw crusher, as one of the most widely used stone crushing equipment, is mainly used for coarse crushing of materials with hardness ≤320Mpa. It has the advantages of large crushing size, high output, simple structure, reliable operation, easy maintenance and low operating cost.

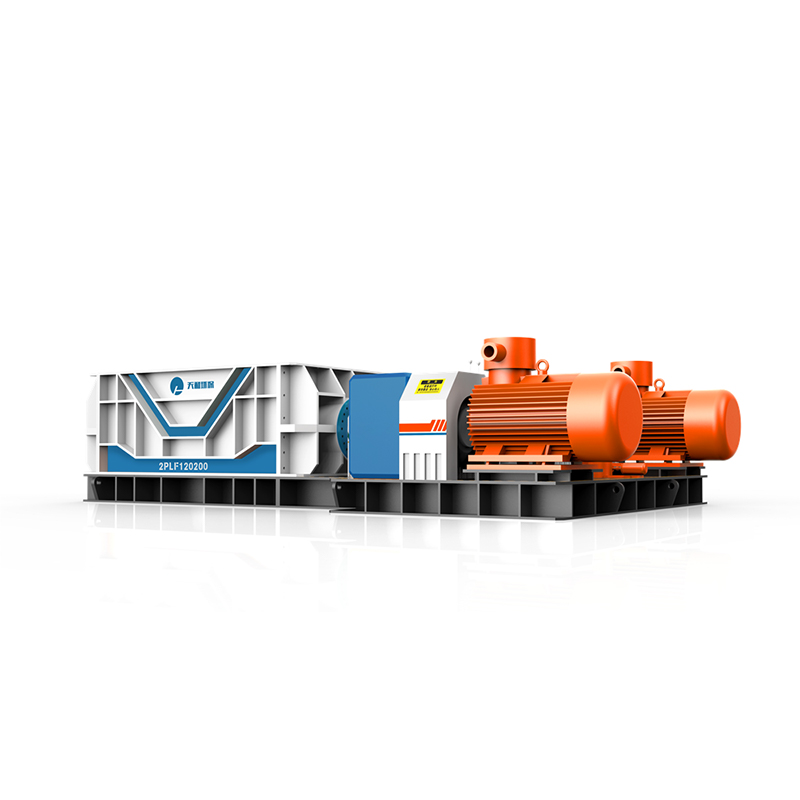

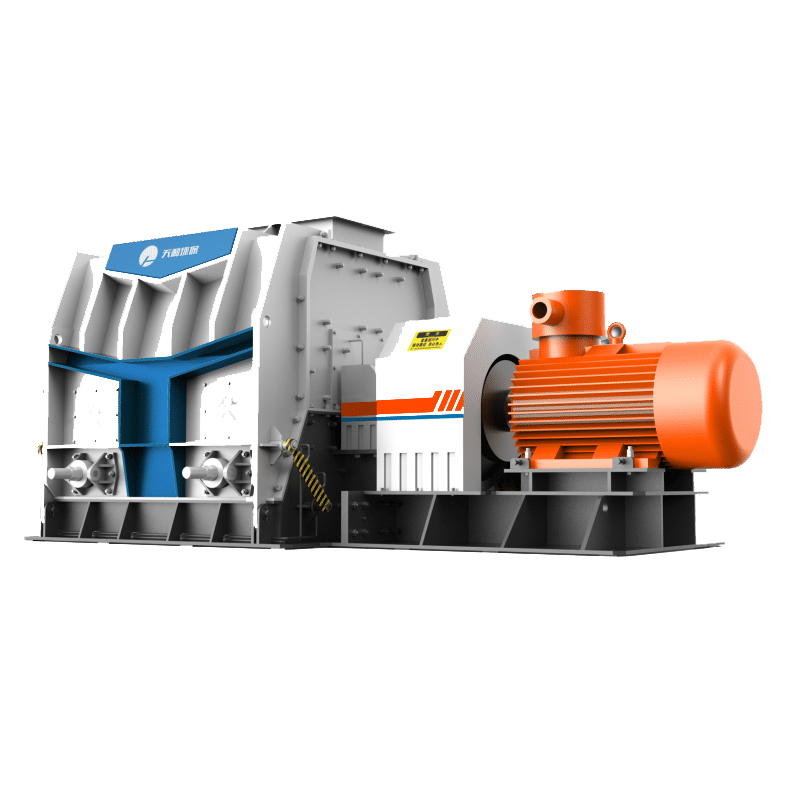

※ 2DSKP series double tooth roller crusher for secondary crushing and shaping of limestone, can reduce over crushing to the greatest extent, improve the lump rate of calcium carbide products 40-90mm or 20-40mm limestone size rotary kiln feed products ; Through shear, tensile crushing effect, greatly reduce the long strip, sheet material, powerful promoted the sales of finished goods, to ensure the quality of the downstream of finished goods, improve the whole production efficiency of the whole production line, achieve the optimal use of limestone resources;

※ GS series reciprocating screen, has the advantages of simple structure, economical and practical, convenient maintenance, distribute the feeding limestone evenly, meticulous sizing, etc.

※ Y, YK series sizing screen is a multi-layer, efficient new vibrating screen, the machine uses small amplitude, high frequency, large dip angle structure, to achieve high screening efficiency, large processing capacity, long service life, low power consumption, low noise and other advantages.

LUMP RATE PERCENTAGE AND FINAL MATERIAL SHAPE CONTROL METHOD

※ Limestone feeding control: The feeding method adopts grizzly type vibrating feeder/heavy plate feeder + feeding grizzly bar. Before entering the jaw crusher for primary crushing, the materials with a particle size of ≤300mm do not enter the primary crusher for crushing, and pass through the grizzly sieve and then directly enter the first crushing sizing screen for classification. It avoids over-crushing of materials ≤300mm in the primary crushing process, and improves the lump rate of finished products;

※ The control of sizing screen before the second crushing: the material is classified before entering the secondary crusher for crushing and shaping, and the finished material is passed through the sizing sieve. After sizing, it directly enters the final sizing sieve for sizing. It avoids the over-crushing of finished materials in the crushing process of the secondary crusher, and further improves the lump rate of the finished product;

※ Tianhe Technology double-toothed roller crusher is used as the secondary crushing equipment to control the crushing and shaping of the material: the double-toothed roller crusher has the characteristics of the highest lump rate and the best shaping effect. Compared with the traditional jaw crusher, hammer crusher or cone crusher for secondary crusher, the double-toothed roller crusher can improve the lumping rate of the incoming material by at least about 20%; The controlled pre-tooth space, the space between adjacent teeth and the arc length of the two tooth tops are specially designed to maximize the lump rate, which is 2%-5 higher than other manufacturers' double-tooth roller crushers in terms of lump rate percentage;

※ The design of the closed-circuit circulation system for the return material is the last process control to improve the limestone lump rate. After optimizing the design, the center distance between the two toothed rollers can be increased or decreased by adjusting the product discharge particle size to ensure a certain proportional relationship between the finished product and the returned material, in order to achieve the maximum lump rate requirement.

PROJECTS PROFILE

600tph Limestone Crushing Plant

800tph Limestone Crushing Plant